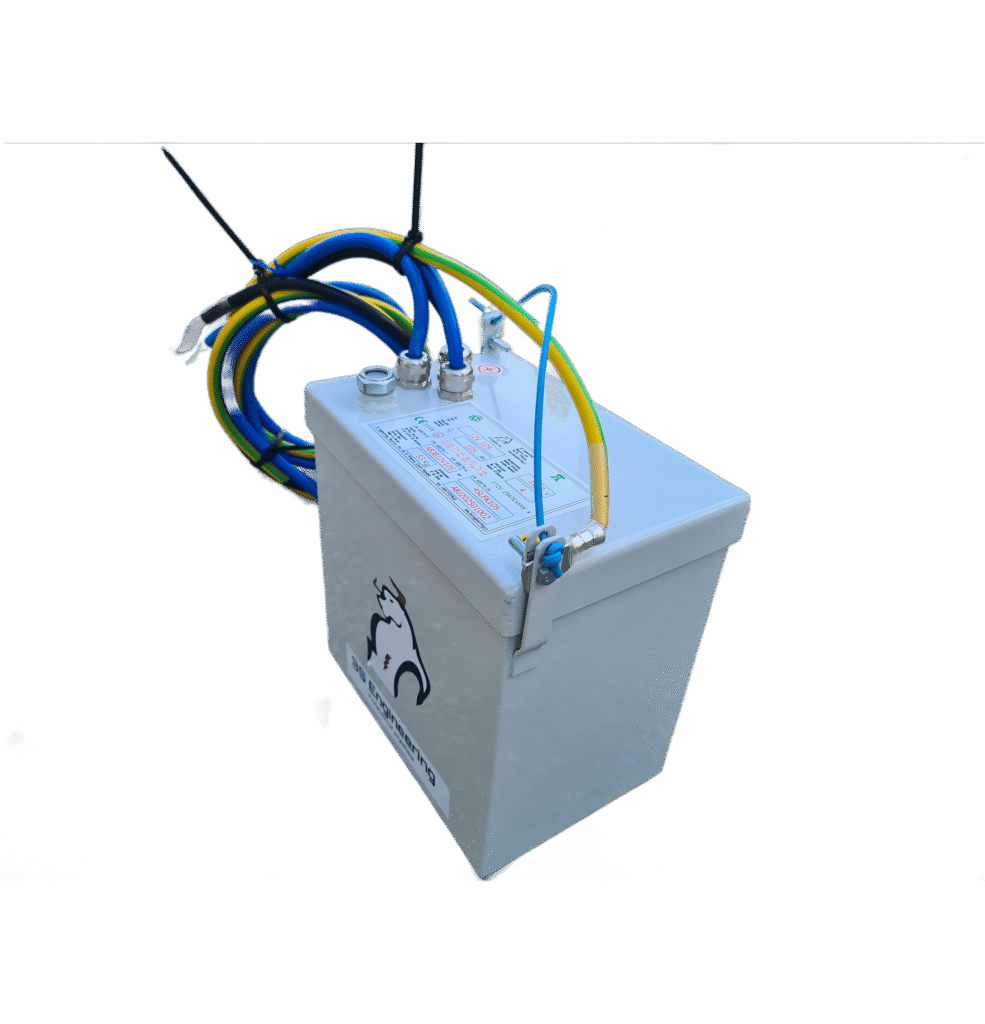

The project of Lithium-Ion battery module development is to introduce compact solution with Lithium-Ion battery used as a motive power battery. It is mostly used to energise various machines like electric forklifts, cleaning machines and also large machines like locomotives for the mining industry.

The aim is to develop a compact solution of a battery block / module which can be used instead of conventional source of energy (lead-acid batteries), and can also be used in hazardous location classified according to EN/IEC 60079-10 and Directive 2014/34/EU with increased safety features.

Advantages of Lithium-Ion batteries

- one of the highest energy densities (100-265 Wh/kg or 250-670 Wh/L)

- cells can deliver up to 3.6 Volts, (large amounts of current for high-power applications)

- low maintenance

- cycling to maintain their battery life is not needed.

- nearly no memory effect

- low self-discharge rate (±1.5-2% per month)

Disadvantage of Lithium-Ion batteries

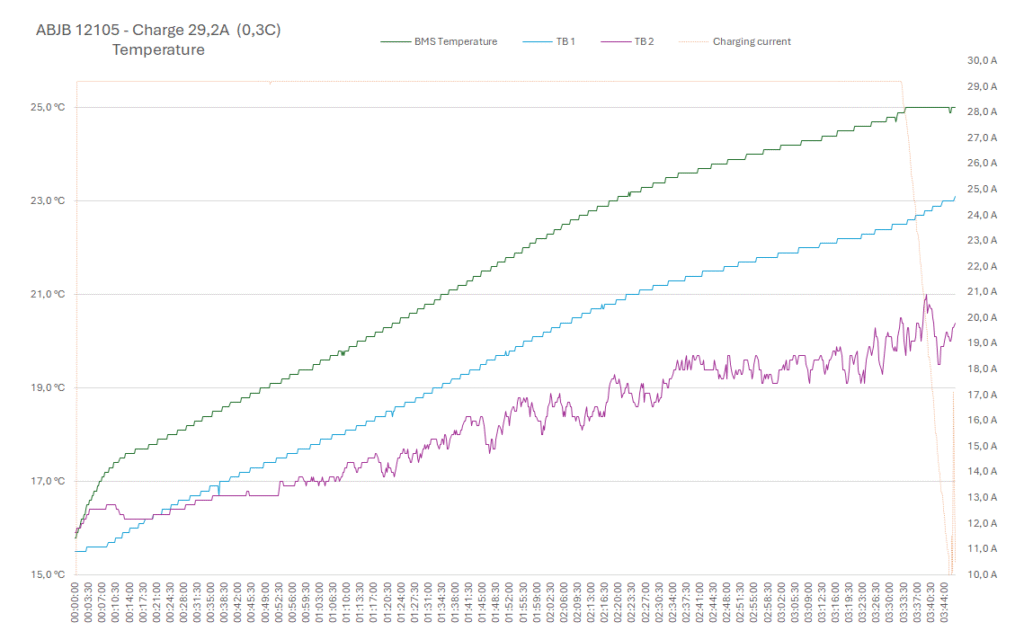

- a tendency to overheat

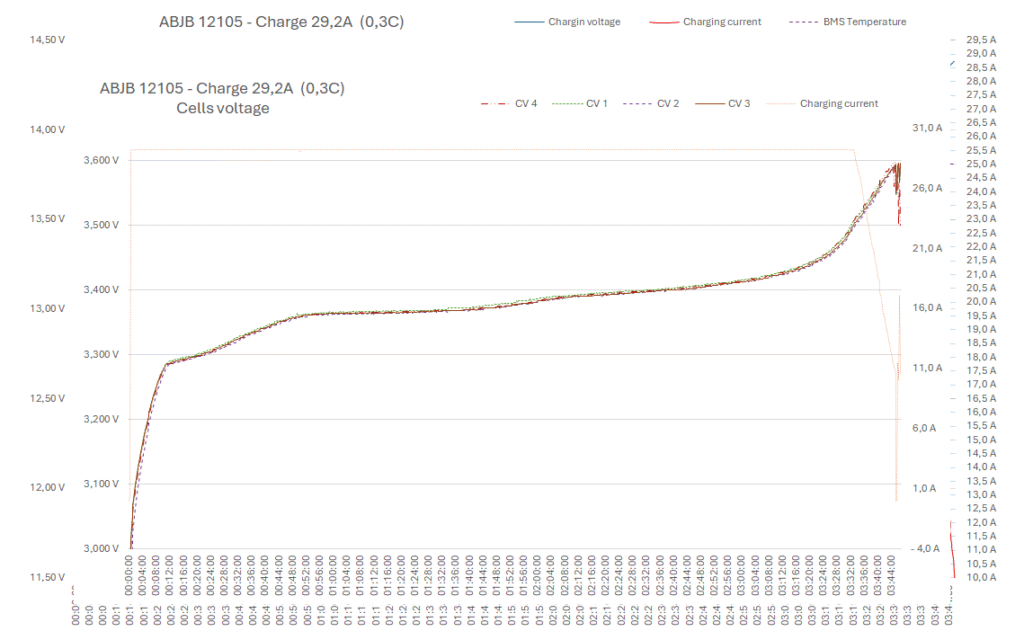

- can be damaged at high voltages (this can lead to thermal runaway)

- safety mechanisms to limit voltage required

- internal pressure monitoring required

- subject to aging (can lose capacity within number of years)

Technical description of Lithium-Ion battery module

Cell type

With respect to severe conditions which might occur during battery module operation, following criteria were used for cell type selection

- High mechanical stability (vibration during operation)

- Temperature resistance (temperature rise under load)

- Electrical parameters (load capacity by discharge current)

- Safety on cell level (safety features)

Based on above mentioned criteria, a prismatic LiFePO4 cell type was chosen